What Are You Looking For?

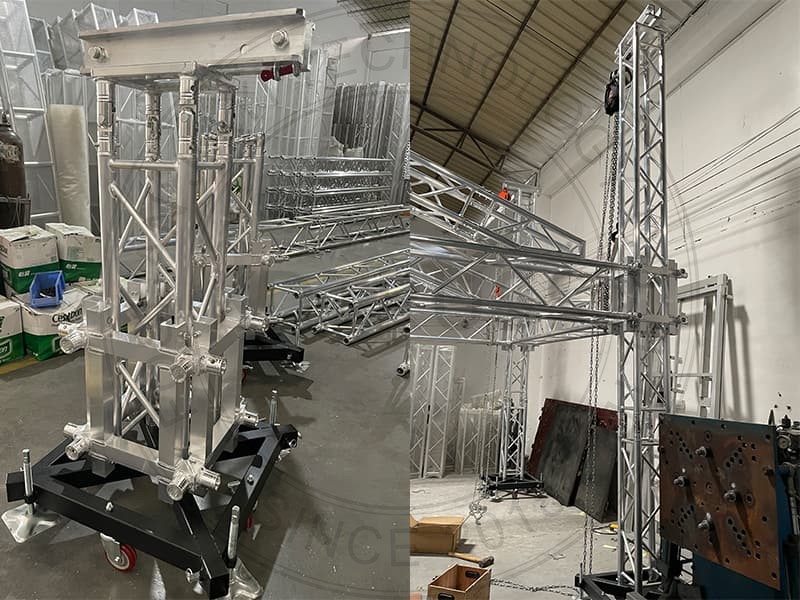

Ground Support Truss Tower is a truss structure generally used as a column to support overhead truss and can be used as a free-standing tower for lighting or audio applications or can be part of a multi-tower roof system. A basic 4-Post system would be a small roof or canopy structure that has 4 towers or “Pillars”.

Item No :

JY-MPTOrder(MOQ) :

1 setsPayment :

30% deposit, 70% balance before delivery goods.( standard goods)Product Origin :

ChinaColor :

Sliver / BlackShipping Port :

Gunagzhou/Foshan/ShenzhenLead Time :

3-15 working daysWeight :

115kgThe Truss Tower makes for an excellent vertical truss that allows the safe, quick lifting of regularly loaded Truss Roofs to their service height. The width of the main span, the height of the towers and other variables such as outdoor wind loading or seismic loading are all taken into account in the design of Ground Support Truss Towers.

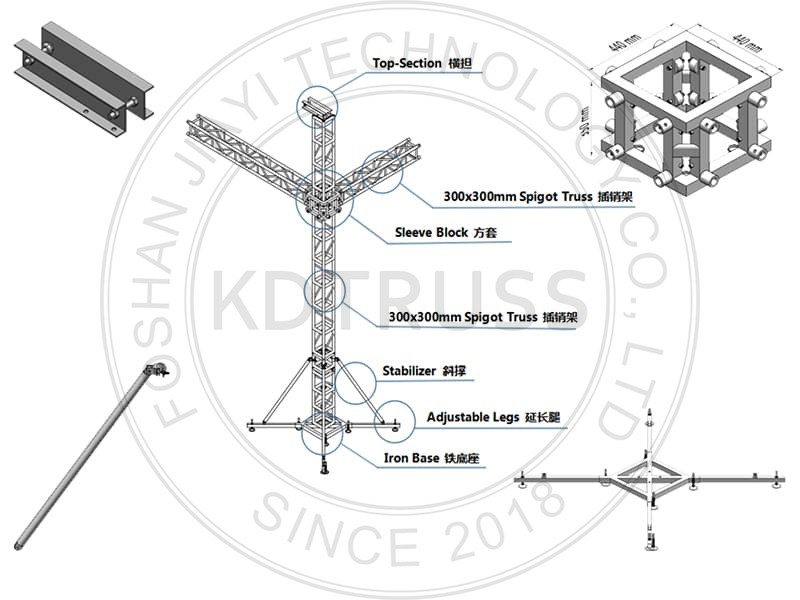

A Ground Support Truss Tower including:

Top Section: A new multifunctional top part for use of manual chain hoist as well as Electric hoist has been redesigned and built stronger.

Straight Truss: The main span, as the name says is the primary span of truss running horizontal between the vertical towers. This horizontal truss span allows for the attachment of moving lights, video production, automation and many other devices.

Sleeve Block: The Sleeve Block attaches to the main truss span and contains internal wheels that provide a sleeve for the tower truss. Sleeve blocks are manufactured in different sizes and variations to accommodate different sizes of tower truss and main span truss.

Hinge: The Tower Truss Hinge Section is a short hinging tower that is designed to allow for easy and safe erection of towers. The complete tower may be assembled at the ground level and hinged up into place using a tower lifter.

Long Outrigger: Outriggers provide additional stability at the base of a tower truss to help resist lateral loads such as wind or seismic activity. They also provide a measure of safety during erection to help the towers stand freely prior to completing erection. The leveling feature of the outrigger allows the end-user to adjust the leveling pads for a firm contact on the ground or support surface. The leveling outriggers can conveniently rotate and adjust from side to side for ease of installation.

Steel Base:Steel Base on wheels available with short outriggers and long outriggers in combination with stabilizer bars.

In most applications the bottom of the Truss Tower will have a Steel Base providing the tower with a firm platform on which to stand. The leveling Base Plate mounts to the bottom of the truss tower and bolts into the foundation or support surface. The leveling feature allows the base plate to be adjusted so that it is firmly positioned on the foundation and also allows the user to level the truss tower once it is up and in place.

| Truss Tower technical specifications | |

| Max. height | 7m |

| Max. loading capacity | 1000kg |

| Max. loading hoist | 2000kg |

| Type mast sections | 290*290mm square truss |

| Sleeve block suitable for truss-series | 290*290mm/ 400*400mm square truss |

| Alloy alu parts | Aluminum Alloy 6061-T6 |

| Coupling system tower | F34Truss accessories |

| Colors | Sliver / Black |